Simulation Based Scheduling

Simulation Based Scheduling

The last 10 years, we have witnessed a trend that our customers want to maximise the benefits of a simulation model. Therefore, we build more and more applications that support the planner with complex daily scheduling issues. The simulation model is supplied with orders from ERP, complemented with a Graphical User Interface (for the planner) and Mathematical Optimisation Techniques (to earn the €’s).

Orders for the next day / week can already be sent to your virtual factory to make the right planning decisions. It is also possible to connect the simulation model directly to the MES or control layer (PLCs). Reality and simulation come even closer, and for example status information can be used to quickly estimate the influence of Rush orders.

Customers are excited about Simulation Based Scheduling and report a ROI of less than 6 months! This raises our customers and our services to a next level of optimisation, the ‘Smart Digital Factory ‘.

ProPLAN – Simulation Based Scheduling for SMEs

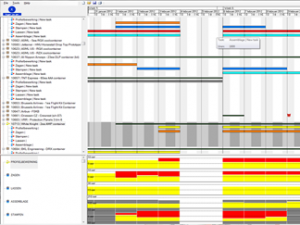

Little time and yet stay in control of the available capacity of people and machines. A daily dilemma of many production managers and planners. Our planning tool hereby provides successful outcomes thanks to overview, flexibility and speed.

Excel is a widely-used tool within SMEs for the production planning of the manufacturing and assembly capacities. However, vital functionalities to make plans flexible, fast and visually clear often lack. These shortcomings are overcome by our planning tool ProPLAN. In a graphical and user-friendly manner, ProPLAN provides quick insight into the available capacity.

The available capacity is adjusted daily (absence, maintenance) and the distributed work is imported, including accompanying deadlines. A “Gantt chart” makes immediately clear where scheduling problems occur. This allows the planner or production manager to quickly decide what changes are needed and immediately show the consequences to colleagues. The application is developed by Ergo-Design in a modular way, which enables any adjustment to specific requirements.

Interesting for you? Why not invite us for a presentation?

Simulation Based Scheduling

Simulation Based Scheduling