Ergonomic workplace

Ergonomic workplace

When a man plays a central role in a (line) station, we call it a workplace. We are regularly confronted with problems resulting from poor workplace ergonomics. Our goal is to resolve this as quickly as possible, but, even better, to prevent this. Prevention through good workplace design should be the rationale. By means of a task analysis and task allocation we determine which tasks are carried out by people and which are performed by machines. Then, in consultation with your employees, the workplace is designed, taking into account the technical and ergonomic requirements. The human tasks must form a coherent set in which the intended occupation should be adequately performed without overloading the workers.

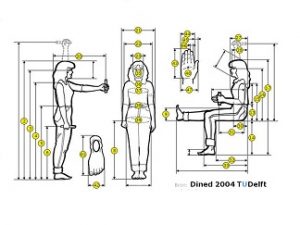

The workplace dimensions should be tailored to the staff population (anthropometry – See picture on the left – dined . TUDelft ). The operator needs to receive sufficient and correct information on his screen. In addition to safety, health and efficiency, this also contributes to the image you have as an employer. Employees working until age 67 or older make the importance of good Ergonomics even more significant. When designing manufacturing and logistics operations, we use our extensive experience in correctly matching the working environment and tools with human possibilities. Our registered ergonomists and Industrial Engineers are at your service for realising the perfect ergonomic workplace.

Measuring physical strain based on scoring methodologies

A quantitative evaluation of the physical load and the possible improvements may be needed to motivate investments in the workplace or tooling. With an expert eye and the right methodology, Physical Strain can be adequately expressed in an objective score. Over the years, we have assessed and improved many physically demanding activities. We use a wide range of scoring methods (e.g. NIOSH / EAWS / AAWS / AWS light / load profiles) to objectively determine the load, and to match this with the (limited) capacity of the staff (including profile system for Scania). Of course, the subjective experience of the employees is also taken into account.

Ergonomic training for engineers that aim for the best ergonomic workplace

The Dutch Society of Ergonomics (NVvE) defines ergonomics as follows: “The discipline of ergonomics concerns the interaction between people and the designed technical and organisational environment. In product ergonomics, we strive to develop user-friendly products, and in production-ergonomics, we strive to develop-human friendly (production)-processes.” In addition to social goals, ergonomics can contribute to the economic goals of an organisation.

With human-friendly production processes, a company can increase productivity and thereby achieve significant cost savings. Because of the growing awareness of the importance of people (customers and staff) for the success of organisations, ergonomics can be of strategic value for the management of organisations. Our registered ergonomists (Eur.Erg.) have been providing in-company courses in the field of “Ergonomics and Efficiency of Production” for many years. These are practical courses for companies such as Philips, Scania, DAF, Holec, Bosch, Shell, NAM, etc. Participants are mainly process engineers, production or manufacturing engineers, industrial engineers and occupational health staff. We are happy to discuss your wishes to come with an appropriate proposal. Examples are:

- Ergonomics awareness in Production environment 1 day

- Ergonomics awareness in Production environment 2-4 days

- Background and use of EAWS 2-4 days

- Using AWS light 1 day

Ergonomic workplace

Ergonomic workplace