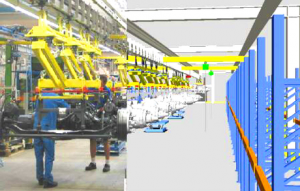

Scania Zwolle

Axle assembly line

The accompanying picture shows the result of the axle line, which is the supply line for the two main assembly lines for trucks. Ergo-Design was responsible for the development, concept engineering and project management up to the realisation. The axles come from Scania Sweden and are equipped with the proper suspension and brakes on the assembly line, in accordance with the demands of customer and in truck delivery order. The right expertise, backed by with our 3D software, resulted in a good line design including layout, tooling and logistics specifications. Efficiency and ergonomics are obviously fully included. Good preparation contributed to the entire line being built and taken into operation within 3 weeks.